Automation System for Water Supply and Sewage

At the current stage of water processing technology water supply and sewage control is not possible without their automation. Automation of water supply systems usually help to maintain the set pressure, temperature and pump and shut-off equipment control. Automation of sewage usually helps to operate valves and pumps and to maintain water level in drain pits.

Automation of complex water treatment processes is done based on deep knowledge of the process and based on knowledge of automatic control principles.

Water Supply System Power Saving

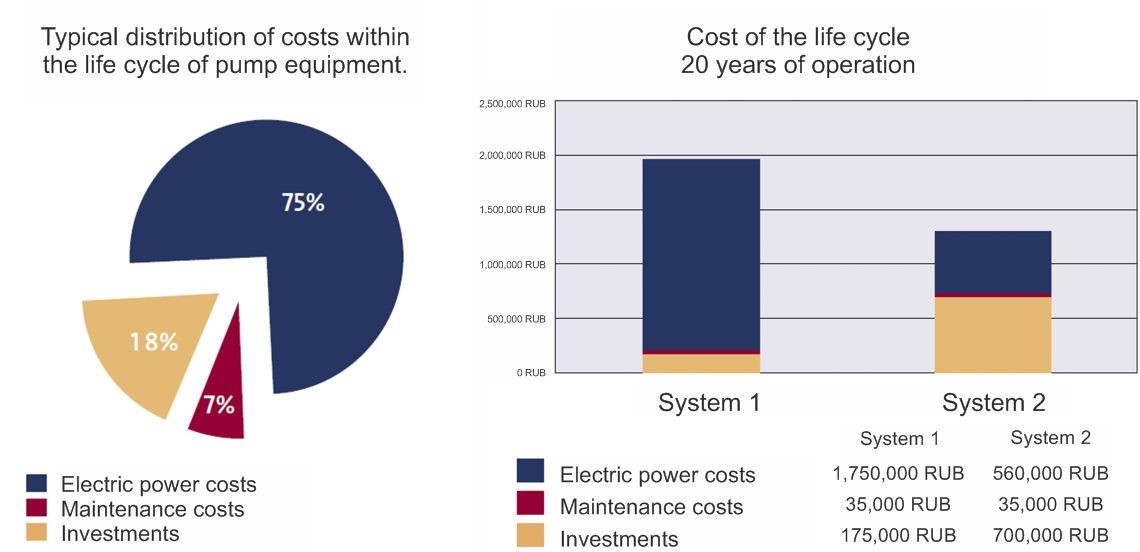

Around 20% of world electrical power consumption is covered by pump equipment. In some engineering systems installation of controllable pumps enables to economize up to 50% of electric power.More expensive equipment often has a longer service period and is more power efficient, as in case of controllable pumps. Therefore, the purchased equipment define the costs within the life cycle.

The cost of the life cycle is determined by the following costs:

- investment costs

- mounting and commissioning costs

- electric power costs

- operating costs

- maintenance and repairs

- equipment downtime

- ecological costs

- dismantling and disposal

Pump Control Cabinets

ST Solution offers a standard range of pump unit control cabinets for optimization of the cost and delivery terms:Main functions:

- electric power supply quality control

- remote actuation and disconnection of the unit

- remote setting of the unit operability

- shift into a power saving mode with an external signal

- operation of the unit according to the schedule

- forced emergency actuation of the pumps (for example, in case of fire)

- emergency indicator

- protection from freezing of water in the outdoor container

- connection to the dispatching system

Pump control:

- individual control of pumps in automatic and manual mode

- pump start control

- protection of the pump from dry running

- local control switch position monitoring

- smooth pump operability control

- automatic standby of the pumps

- jamming protection

- calculation and balancing of the pump service hours

Connected instrumentation:

- pressure transducers

- flowmeters and level sensors

- temperature sensors

- external air temperature, pump room temperature

- other sensors, water quality sensors

- sensors and protection relay (general protection relay against dry running, pressure differential relay at each pump)

Development of unstandardized cabinets specially for you is possible upon request.

Ru

Ru En

En